Are you wondering how to size a back-flow preventer for your home or business? You’re not alone.

Many people find themselves puzzled when it comes to this crucial component of plumbing systems. A properly sized back-flow preventer is essential for maintaining the safety and efficiency of your water supply. It protects against the contamination that could compromise your health and the integrity of your property.

Imagine the peace of mind knowing your water is clean and safe, all because you’ve chosen the right-sized device. In this guide, you’ll discover the simple steps to correctly size a back-flow preventer, ensuring you make the right choice without any hassle. Keep reading to unlock the secrets to safeguarding your water supply.

Credit: www.reddit.com

Importance Of Back-flow Preventers

Back-flow preventers play a crucial role in safeguarding your water supply. They ensure that contaminated water doesn’t flow back into clean water lines, protecting your health and the environment. Without them, you risk exposure to harmful substances that can affect your well-being.

Imagine turning on the tap and wondering if the water is safe to drink. That’s a reality without a back-flow preventer. These devices are essential in preventing water contamination from pesticides, chemicals, or harmful bacteria.

Back-flow preventers are not just for industrial or commercial use. They are equally important in residential settings. Whether you have a sprinkler system or a pool, you need assurance that the water remains clean and safe.

Consider this: A simple hose left submerged in a pool can siphon dirty water back into your drinking water supply. Back-flow preventers eliminate this risk, ensuring peace of mind for you and your family.

Why Should You Care?

Have you ever experienced a boil water advisory? It’s inconvenient and can disrupt your daily life. Back-flow preventers can help reduce the chances of such occurrences by maintaining water purity.

Think about the impact on local ecosystems. Preventing back-flow keeps rivers, lakes, and other water sources free from pollution. You contribute to environmental preservation by installing a back-flow preventer.

If you’re involved in gardening or landscaping, back-flow preventers are crucial. They prevent chemicals from fertilizers or pesticides from contaminating your water supply, ensuring your garden stays beautiful and safe.

How Does It Affect Your Wallet?

Installing a back-flow preventer can save you money in the long run. Imagine the costs associated with cleaning up a contaminated water system or dealing with health issues from polluted water.

You might think it’s an unnecessary expense, but consider the potential losses from water damage or contamination. Investing in a back-flow preventer is a wise decision, both financially and for your peace of mind.

Have you ever had to pay for water testing or purification services? With a reliable back-flow preventer, those expenses can be minimized, allowing you to allocate your resources elsewhere.

Are You Prepared For Emergencies?

Unexpected events can compromise your water supply, like natural disasters or system failures. Having a back-flow preventer means you’re ready to handle these situations effectively.

Think about the safety of your loved ones. In emergencies, clean water becomes a priority. A back-flow preventer ensures that your water remains uncontaminated and safe to use.

Are you confident in your home’s water safety plan? Ensuring you have a back-flow preventer is a proactive step in emergency preparedness. Don’t wait until it’s too late to prioritize your water safety.

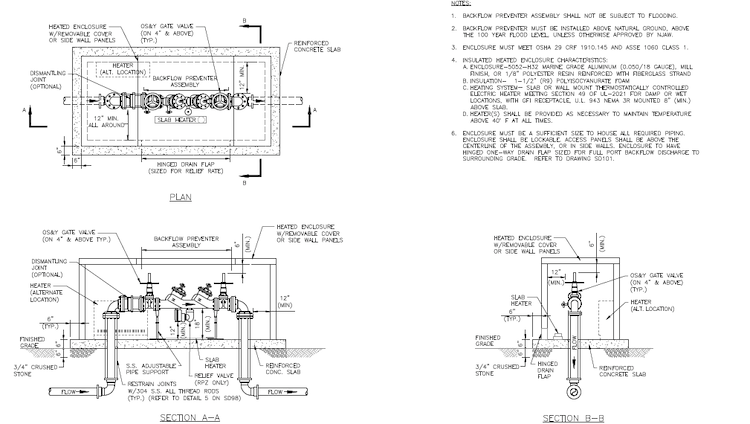

Credit: www.safe-t-cover.com

Types Of Back-flow Preventers

Choosing the right back-flow preventer is crucial to protect your water supply from contamination. The types of back-flow preventers vary based on your specific needs and the nature of the water system. Understanding each type can help you make an informed decision that safeguards your health and environment. Let’s dive into the details of the most common types you might encounter.

Reduced Pressure Zone

The Reduced Pressure Zone (RPZ) device is often used in high-risk areas where contaminants could pose severe health risks. It features two independent valves with a pressure relief valve between them. This design ensures that even if one valve fails, the other will maintain the barrier against back-flow.

Imagine you’re maintaining a complex irrigation system. An RPZ device can be your best ally, offering peace of mind that your drinking water remains uncontaminated despite potential failures in the system. Have you considered the risks involved in not having this level of protection?

Double Check Valve

The Double Check Valve assembly is a reliable solution for medium hazard situations. It consists of two check valves that work in sequence to prevent back-flow. If one valve fails, the other provides a backup, ensuring continuous protection.

This type is suitable for residential areas where the risk of contamination is moderate. Think about your neighborhood pool or garden sprinkler system. A Double Check Valve could be the perfect fit, offering effective protection without overcomplicating the setup.

Pressure Vacuum Breaker

The Pressure Vacuum Breaker (PVB) is designed for areas with low contamination risks, often found in irrigation systems. It prevents back-flow by using a check valve and an air inlet valve, which opens to break the vacuum when the water pressure drops.

Consider your backyard drip irrigation. A PVB can ensure that any potential back-flow doesn’t compromise your water quality. It’s simple yet effective, making it a popular choice for homeowners looking for straightforward protection.

Choosing the right type of back-flow preventer isn’t just about compliance; it’s about ensuring the health and safety of those who rely on your water system. Have you assessed the risks associated with your water supply? Your decision could make a significant difference.

Factors Affecting Size Selection

Sizing a back-flow preventer ensures efficiency and safety in plumbing systems. Several factors influence the size selection. Understanding these factors helps in making informed decisions. Let’s explore the key elements that affect size selection.

Flow Rate Considerations

Flow rate is crucial in sizing a back-flow preventer. It determines how much water the system can handle. Measure the maximum flow rate needed. This ensures smooth operation without pressure drops.

Pipe Size Compatibility

Check pipe size compatibility. The back-flow preventer should match the pipe size. This avoids unwanted pressure changes. Ensure the device fits snugly with existing pipes.

Pressure Loss Assessment

Pressure loss assessment is essential. A mis-sized preventer causes pressure drops. Evaluate the pressure loss through the device. Choose a size that maintains optimal pressure levels.

Credit: www.plumbingsupply.com

Calculating The Correct Size

Sizing a back-flow preventer is crucial for effective water system management. It’s not just about fitting the device; it’s about ensuring optimal function. Accurate sizing prevents leaks and maintains system pressure. Understanding calculations helps in choosing the right size.

Using Flow Charts

Flow charts simplify the sizing process. They visualize water flow rates through different pipe sizes. Check the chart for the flow rate in your system. Match it with the corresponding pipe size on the chart. This gives a quick reference for choosing the correct back-flow preventer size.

Velocity And Pressure Drop Calculations

Velocity calculations involve the speed of water through pipes. Faster velocities may require larger preventers. Pressure drop calculations determine pressure change across the preventer. Ensure the drop doesn’t exceed system capacity. Use standard formulas for these calculations.

Installation Requirements

Sizing a back-flow preventer requires understanding pipe diameter and water pressure. Consider installation space and maintenance access. Proper sizing ensures efficient operation and prevents contamination.

Installing a back-flow preventer is crucial to safeguarding your water supply from contamination. Understanding the installation requirements ensures it functions effectively and lasts longer. Whether you’re a seasoned DIY enthusiast or just dipping your toes into plumbing projects, knowing where and how to install these devices is essential. Let’s dive into the key considerations for installation.

Location Selection

Choosing the right location for your back-flow preventer can make a significant difference in its efficiency. Place it where it can be easily accessed for maintenance. A cramped or hidden spot might cause headaches later when repairs are needed. Consider the proximity to the main water line. Installing it too far might compromise its effectiveness. Have you checked if your chosen location is free from potential hazards like extreme temperatures or physical damage? Think about visibility. Installing it in an unobtrusive area can prevent accidental damage or tampering.

Vertical And Horizontal Installation

Your back-flow preventer can be installed vertically or horizontally. Each orientation has its benefits, but what’s right for your setup? Vertical installation often saves space and provides easier access. It’s ideal if you’re working in a compact area. However, ensure the preventer is stable and not prone to tipping or swaying. Horizontal installation might require more room but can offer better structural support. It’s often used in larger spaces or where vertical placement isn’t feasible. Check the manufacturer’s instructions. They typically provide guidance on the best orientation for your specific model. Are you considering the layout of your plumbing system and how it might affect installation? By understanding these installation requirements, you can ensure your back-flow preventer operates efficiently and protects your water supply. Ready to roll up your sleeves and get started?

Common Mistakes To Avoid

Proper sizing of a back-flow preventer ensures efficient performance and safety. Mistakes during sizing can lead to costly repairs and water contamination. Understanding common errors helps in avoiding them. This section outlines key mistakes to avoid.

Ignoring Manufacturer Guidelines

Manufacturers provide specific guidelines for their products. These guidelines are essential for proper installation and function. Ignoring them can lead to incorrect sizing. This might cause malfunction or failure. Always read and follow the manual closely. It ensures the back-flow preventer fits your system.

Overlooking Maintenance Needs

Regular maintenance keeps back-flow preventers in working order. Many overlook this crucial step. Neglect leads to wear and tear. It might cause system breakdowns. Schedule routine checks as recommended. This prevents unexpected issues and prolongs device life.

Expert Tips For Optimal Performance

Choosing the right size for a back-flow preventer ensures efficient water flow and protection from contamination. Consider pipe size, flow rate, and pressure. Proper sizing avoids costly repairs and maintains system integrity.

Sizing a back-flow preventer correctly is crucial for maintaining the safety and efficiency of your plumbing system. But how do you ensure optimal performance? By focusing on a few expert tips, you can make informed decisions that enhance your system’s lifespan and functionality. These tips don’t just apply to professionals—they’re valuable for anyone looking to safeguard their water supply. Let’s dive into some actionable advice that can make a real difference in your setup.

Regular Inspection And Testing

Regular inspection and testing are vital for optimal performance of your back-flow preventer. You might be wondering why this is necessary. Over time, wear and tear or debris buildup can affect the device’s efficiency. Schedule inspections at least once a year. This helps catch issues early before they turn into costly repairs. Testing ensures the preventer is working correctly, maintaining the integrity of your water supply.

Choosing Quality Materials

The materials you choose can significantly impact the durability and performance of your back-flow preventer. High-quality materials resist corrosion and withstand pressure better. Consider investing in brass or stainless steel preventers. These materials offer longevity and reliability, especially in environments exposed to harsh conditions. While they might be pricier upfront, they save money in the long run by reducing maintenance needs. Have you ever opted for a cheaper alternative, only to face frequent replacements? Choosing quality materials can prevent such hassles. It’s an investment in peace of mind, ensuring your system functions smoothly year after year. By focusing on these expert tips, you empower yourself to maintain a reliable and efficient plumbing system. What actions will you take today to ensure your back-flow preventer is up to the task?

Frequently Asked Questions

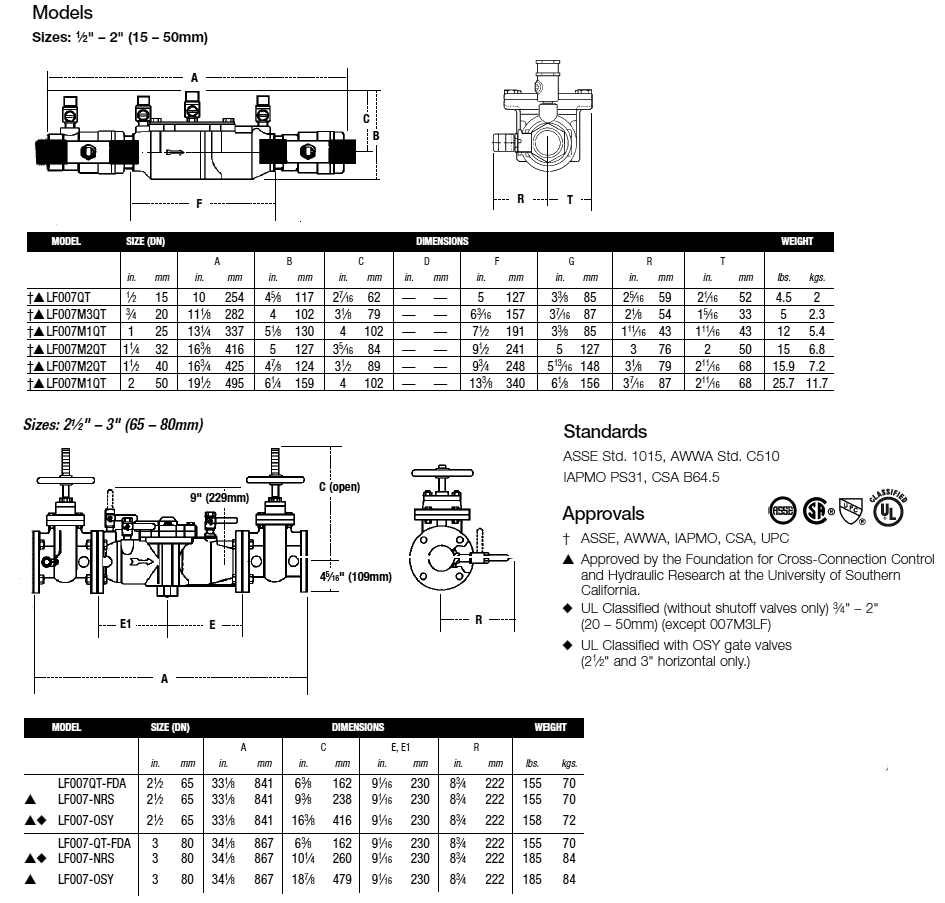

How Do I Know What Size Backflow Preventer I Need?

Determine the size based on pipe diameter, water flow rate, and pressure requirements. Consult installation guidelines for specifics.

How To Size A Rpz?

To size a RPZ, consider the flow rate and pressure requirements of your system. Check the pipe diameter and match the RPZ to ensure optimal performance. Consult manufacturer specifications for precise sizing guidelines. Proper sizing ensures effective backflow prevention and system efficiency.

What Backflow Preventer Do I Need For My Sprinkler System?

Choose a Pressure Vacuum Breaker (PVB) for basic protection. Opt for a Reduced Pressure Zone (RPZ) if high hazard protection is required. Consult local codes and professionals to ensure compliance and safety for your sprinkler system.

What Height Does A Backflow Preventer Need To Be?

A backflow preventer should be installed at least 12 inches above the highest downstream piping or outlet. This elevation helps maintain proper function and prevents contamination. Always consult local codes, as requirements may vary. Proper installation ensures effective backflow prevention and system safety.

Conclusion

Sizing a back-flow preventer is vital for system safety. Choose the right size to prevent contamination. Measure pressure and flow rate accurately. Use appropriate tools for precise measurements. Consult a professional if unsure about sizing. A well-sized preventer ensures clean water supply.

Improper sizing can lead to system failures. Regular checks and maintenance are crucial. Keep your back-flow preventer in top condition. Protect your water system effectively. Always prioritize safety and efficiency. Following these steps ensures a reliable water supply. Remember, correct sizing makes all the difference.